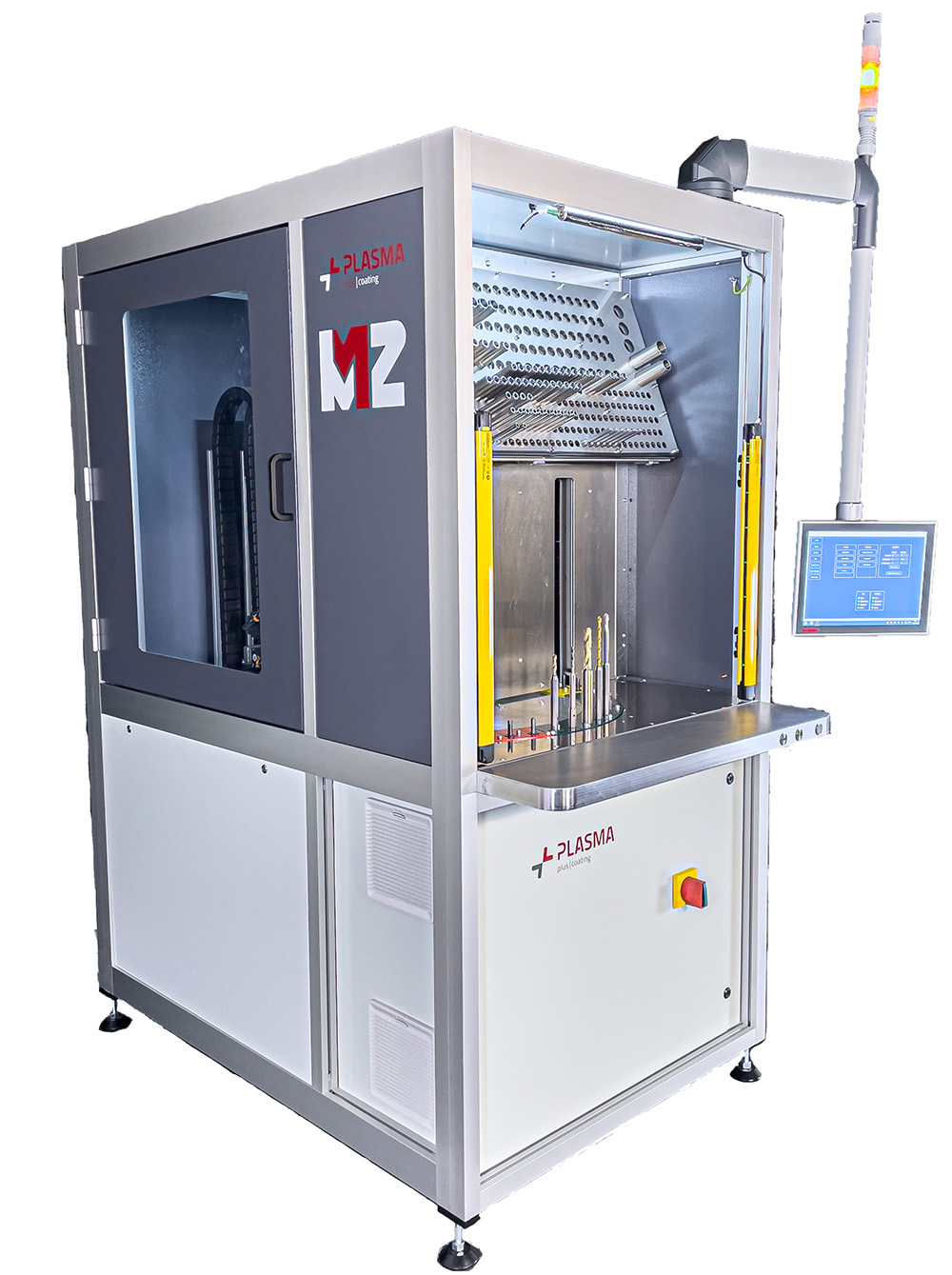

MM2 – 5-axis CNC automatic polishing machine for shank tools

- Polishing processes for shank tools such as drill bits, milling cutters, countersinks, etc.

- Removal of droplets after coating, and polishing to improve chip flow

- Deburring of HSS shank tools or HSS countersinking tools

- Targeted edge preparation and rounding of shank tools before coating

- Increase in punching time through defined cutting edges

- Continuous operation or batch mode possible

- Automatic measurement of the tool length and diameter via optical sensors

- Recipes which can be scaled based on diameter and length for various tool geometries and polishing discs.

- Windows-based Beckhoff PC controller incl. remote maintenance option

- 15-inch touchscreen

- Electrical connection 16 A / 380-480 V

- Simple, menu-guided operation incl. monitoring of all parameters for a reproducible process incl. runtime monitoring of the polishing discs

Technical data

- Fast vertical axis controllable in a range from 0 to 400 mm

- Horizontal axis (infeed) with a travel range from 0 to 80 mm

- Rotating head from 0° to 160° for all common flute pitches

- Speed-controlled servomotor drive for the polishing discs

- Rotary indexing table for mounting up to 40 tools

- Tool diameters from 3 to 32 mm

- Tool lengths from 0 to 400 mm

- Processing times of 5 to 15 sec per tool, depending on the length and type of machining

- Capacity of up to 2,500 tools per shift

Available standard brushes:

- Aluminium oxide brushes with various grain sizes

- Silicon carbide brushes with various grain sizes

- Diamond brushes for polishing processes

Tool holders:

Tool holders available for all common shank sizes